Airflow Sciences Uses Computer Simulations to Track Exhaust Fumes In Local Communities

Natural gas compressor stations are a hidden component of how many people heat their houses, dry their clothes, or cook their food. Usually located in rural areas, they often consist of stacks, vents, large sections of horizontal pipes, and power sources such as gas turbines to power the compressors.

During upset conditions or gas line purges, natural gas is released to the atmosphere. Depending on the pressure and volume of the gas, these plumes may be dangerous if they intersect with ignition sources, or displace oxygen for workers to breathe.

The CFD simulations created by Airflow Sciences allow gas companies to track the gas plumes for different ambient wind conditions. Modeling can be performed "steady state", simulating a continuous emission of gas, or "transient", where the volume of gas being vented varies with time.

For example, Airflow Sciences recently performed external steady-state flow modeling of a natural gas compressor station to determine if vented gas would be ingested into a nearby pair of simple cycle gas turbines. This flow simulation using AzoreCFD highlights the air flow patterns around the station, and tracks the concentration of natural gas as it mixes with atmospheric air.

In order to accurately model the venting and dispersion process, a large portion of the surrounding area, including forests, roads, buildings, and rivers, needs to be incorporated into the CFD simulation. In some cases, the external model geometry may be over a mile in diameter and over 2000 feet high!

Historical wind speeds and directions are obtained, usually from local airports. Analysis of the wind rose in combination with the location of ignition sources or personnel areas determine the ambient wind conditions to model. Often, a series of simulations are undertaken to investigate "what-if" scenarios. CFD results featuring animations, streamlines, or color contours can show the path of the wind, and the effect of buildings, stacks, and other features can clearly be seen.

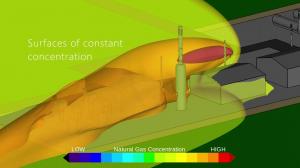

Along with the ambient wind conditions, the mass flow, temperature, pressure, and density of the natural gas play an important role in the plume height and throw. Modeling predicts the path of the natural gas, and streamlines help display this information (see images and video). The model shows how for a particular wind condition, the natural gas plume carries over to the gas turbine intakes and occupied buildings – two potential hazards.

The gas is tracked and analyzed to determine if it is diluted sufficiently so no explosive or dangerous concentrations exist. AzoreCFD uses color bars to display the concentration values, and iso-surfaces allow a quick visualization of potential issues. In the attached image, regions of red and orange indicate that a potentially dangerous situation exists under this scenario. Airflow Sciences works with their clients to offer solutions to mitigate these risks, which may include relocation of stack vents, increasing the height and/or diameter of the vents, or even stack geometry additions such as caps or diffusers.

About Airflow Sciences Corporation

Airflow Sciences Corporation is a fluid dynamics solutions company. They specialize in the design and optimization of equipment and processes involving flow, heat transfer, combustion, and mass transfer. Since 1975, the company has focused on testing and simulation of air, gas, liquid, or particulate flows. They also manufacture standard and custom test equipment, including probes and wind tunnels, so their customers can collect data accurately and efficiently. Their primary CFD software, Azore®, is also available for those customers with in-house CFD personnel. ASC offers comprehensive flow solutions and optimization and serves a wide range of industries including HVAC, power, auto, rail, and food processing.

Contact

For more information on simulations of exhaust gas or to learn how Airflow Sciences can help you mitigate hazardous exhaust scenarios, contact Rob Mudry.

Rob Mudry

Airflow Sciences Corporation

+1 734-525-0300

rmudry@airflowsciences.com

See the CFD model in action: